ICCS is a construction crane operating system which, by connecting to a digital five-dimensional construction plan, offers the crane operator the possibility of having delivery processes carried out partly automatically.

The majority of all goods movements are based on of the construction site are now equipped with a construction crane. The circumstances of construction site and the possibility of heavy loads to be delivered from above must have the crane established.

Course

Bachelor Project

Technologies

Adobe Illustrator

Sketch

After Effects

InDesign

Research

Through informative expert interviews with various stakeholders, such as crane operators, construction workers or site management, we were able to view the entire process of a construction project from all perspectives. We clustered this information on a download poster that supported us during our work.

Furthermore, we spent a day at the construction site and observed the events, which we documented and then evaluated. Hidden user needs will be uncovered, which will further help us to focus on the issues that matter most to us.

We concluded the research phase by clustering all insights into the areas of planning, automation, construction sites and control and writing out the most important ones.

Top Findings

- Short-term, unpredictable changes

lead to a time delay. - Long distances on foot for construction workers.

- Communication between the workers mostly done by body language and eye contact.

- The crane operator is responsible for material procurement.

- Construction workers are rather critical of automation.

Concept

We developed the first version of the concept in a Google Design Sprint. We followed the guidelines of the book „Sprint: How to Solve Big Problems and Test New Ideas in Just Five Days“ by Jake Knapp.

A first version of the revised construction crane control was created, which now resembled more of a logistics and planning application. We then tested this version with users from the construction industry to get as real feedback as possible.

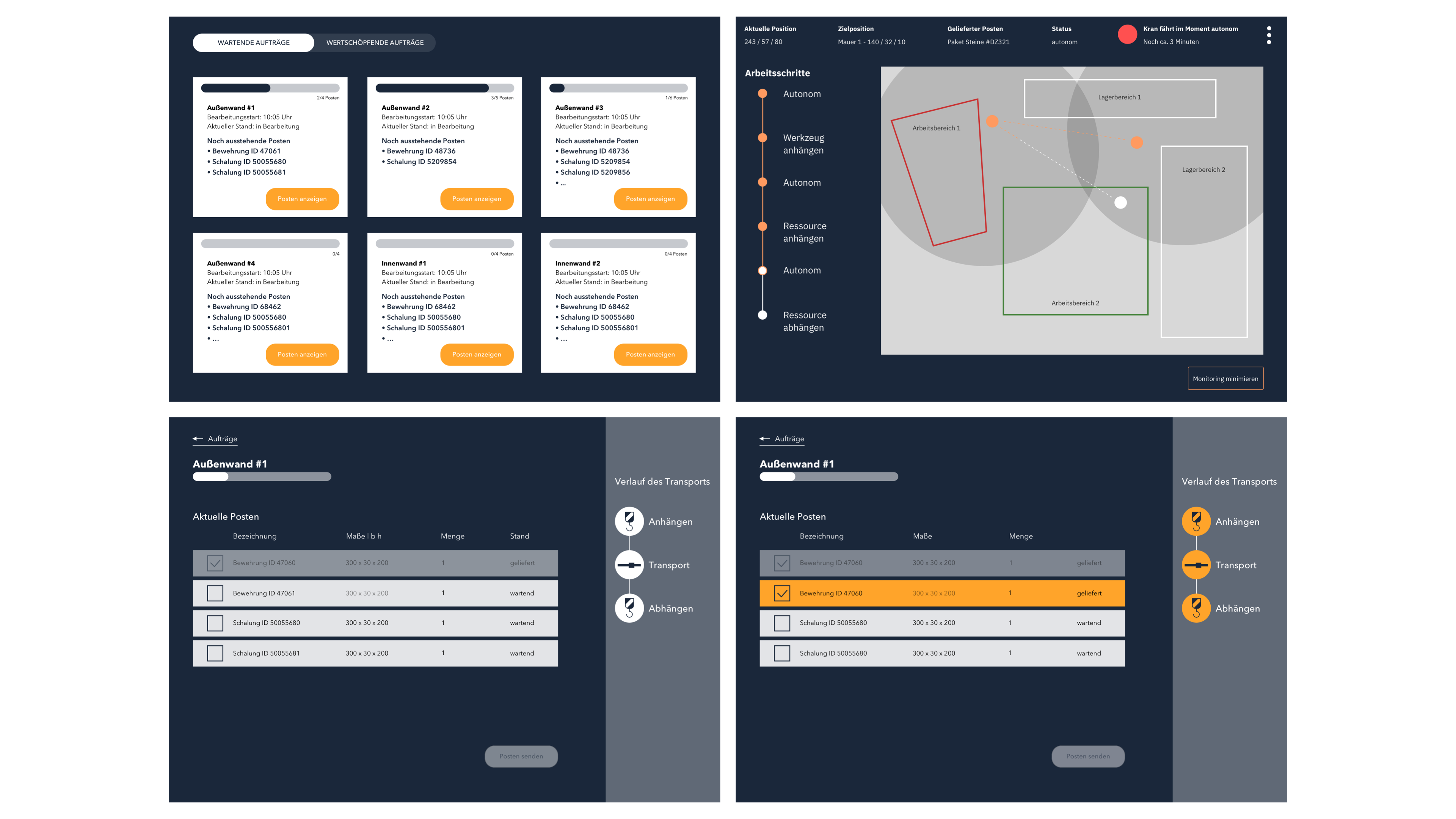

On the following picture you can see the first version of our application.

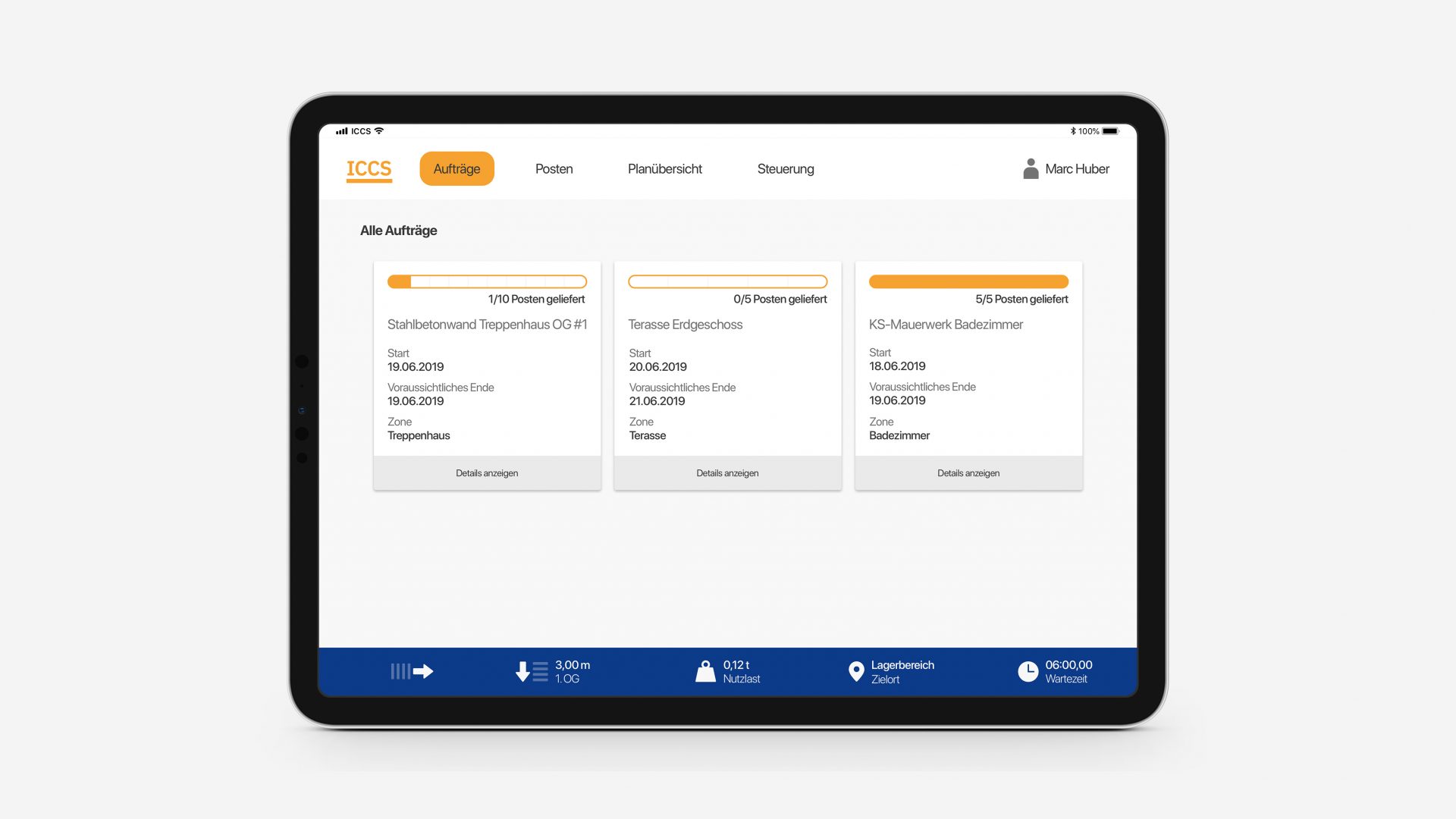

App functions

- Overview of orders

- Detailed view of an order: Number of deliveries

- Live view of the crane (monitoring)

- Current step of the order and status of crane

- Progress of the delivery process

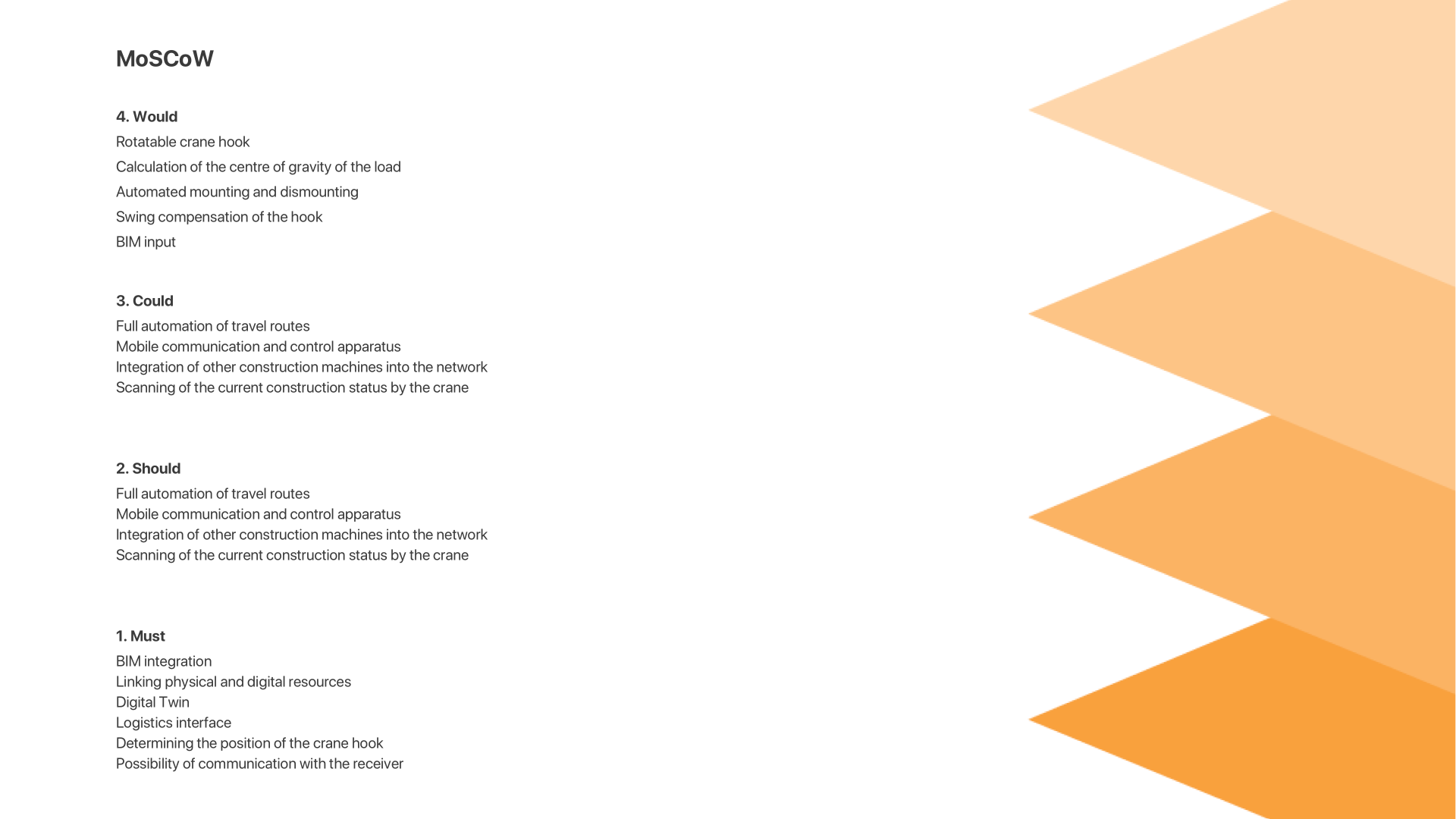

Already after we got into the topic of more concretely and to hold discussions with the with various stakeholders we realized that our system is far more diversified, than initially thought of. The simple revision of a crane control system becomes a much larger concept that will change the way work is done on site from the ground up, with the crane as the central hub.

Opportunity Areas

- networking

- automation

- control

- safety

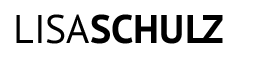

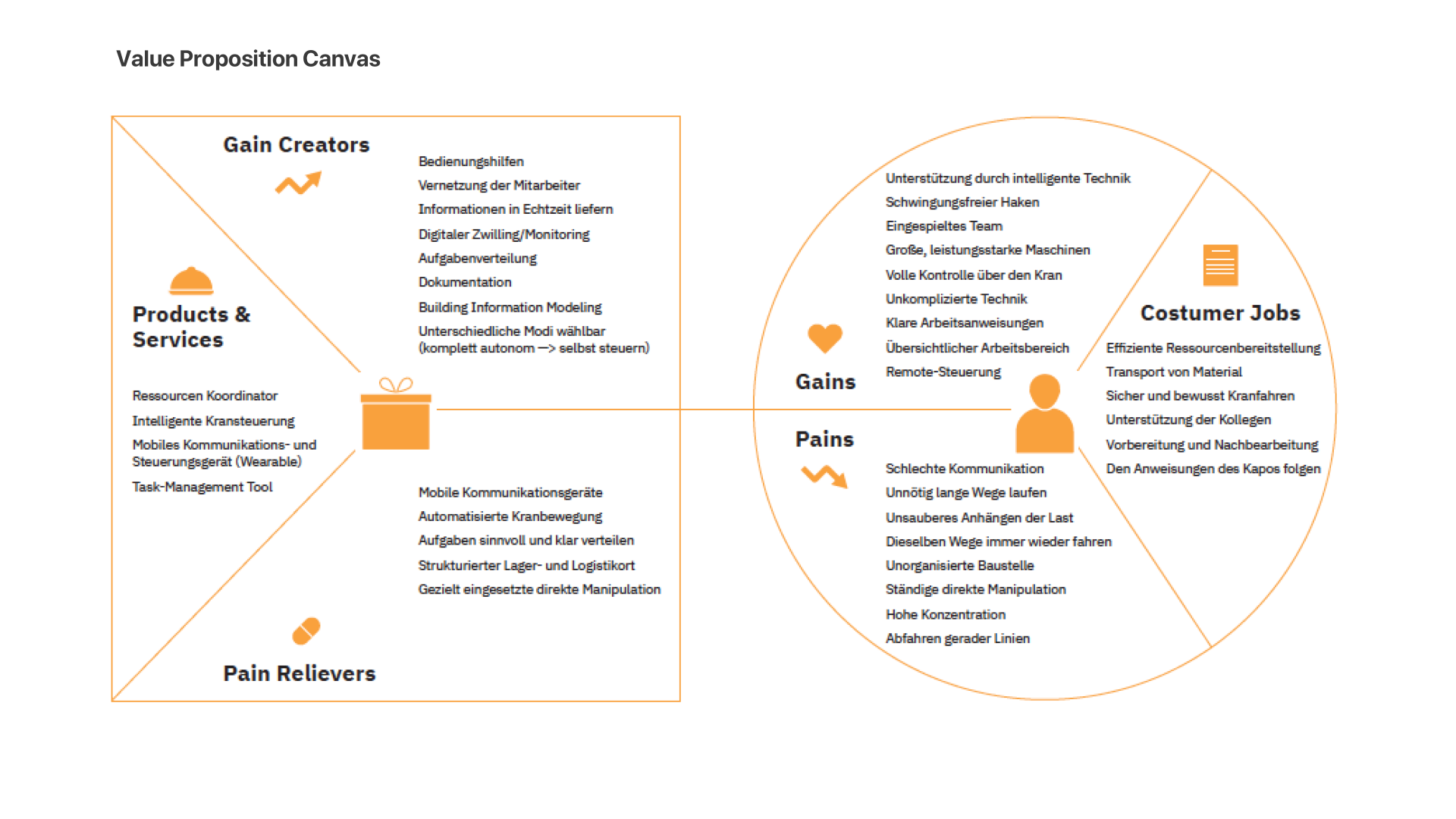

Design Thinking Methods

Approaches

The solution approach will be divided into three main areas: planning, execution and documentation. Each area consists of several components, which are used for the execution of the following tasks of the work are necessary. The foreman is assigned the planning, the crane operator and the construction worker take care of the execution and the documentation happens automatically in the background while the system is being used.

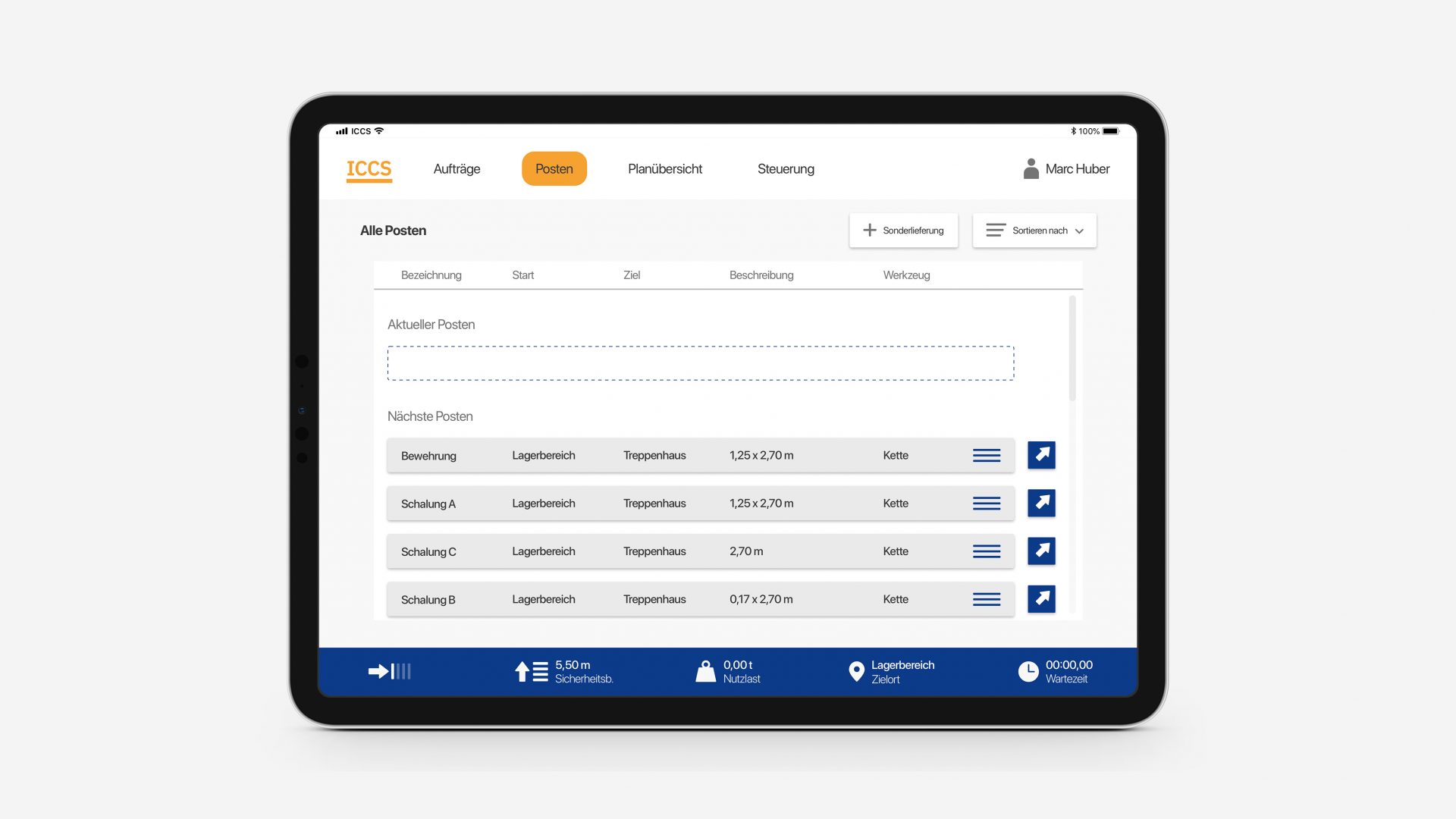

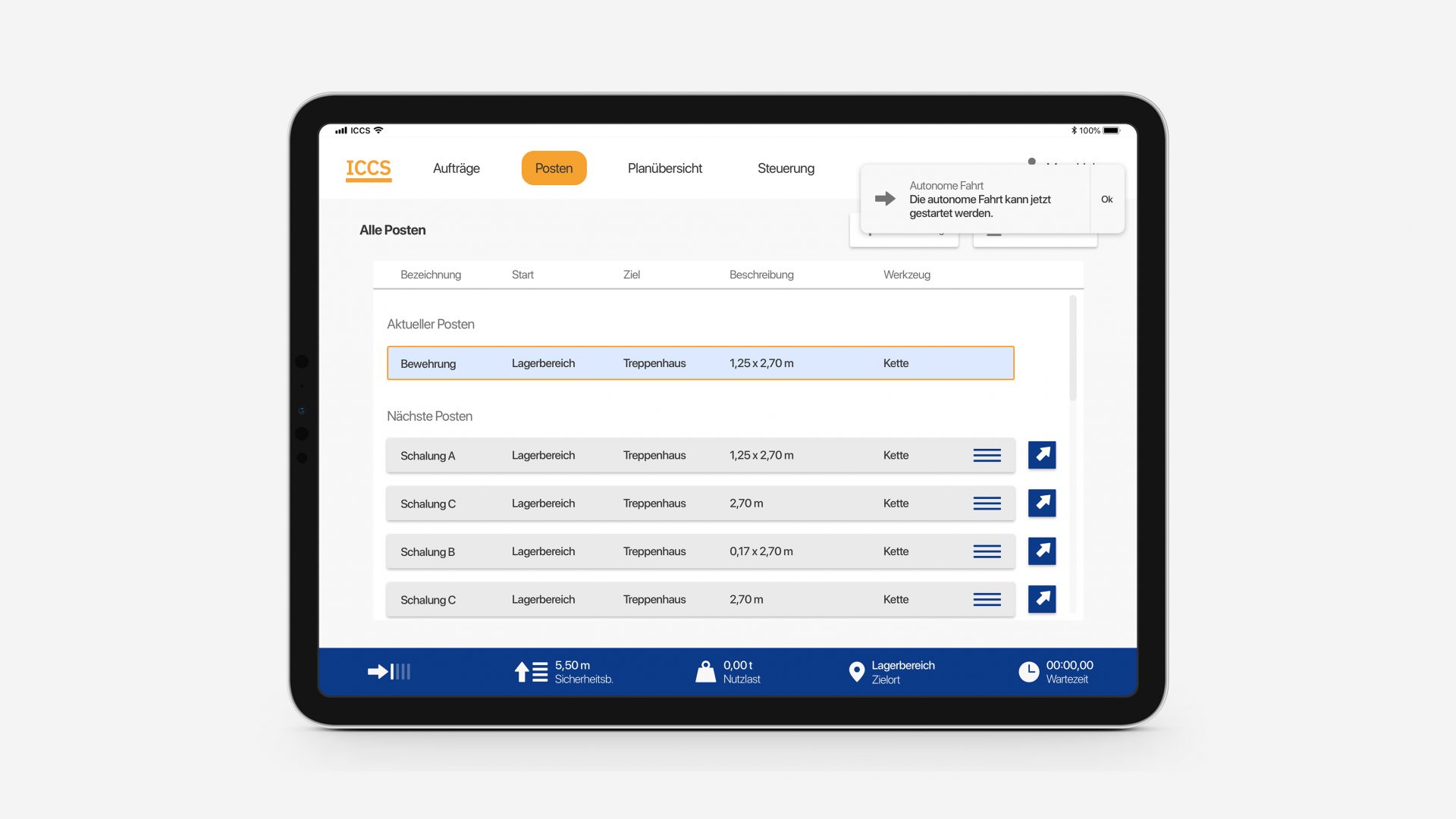

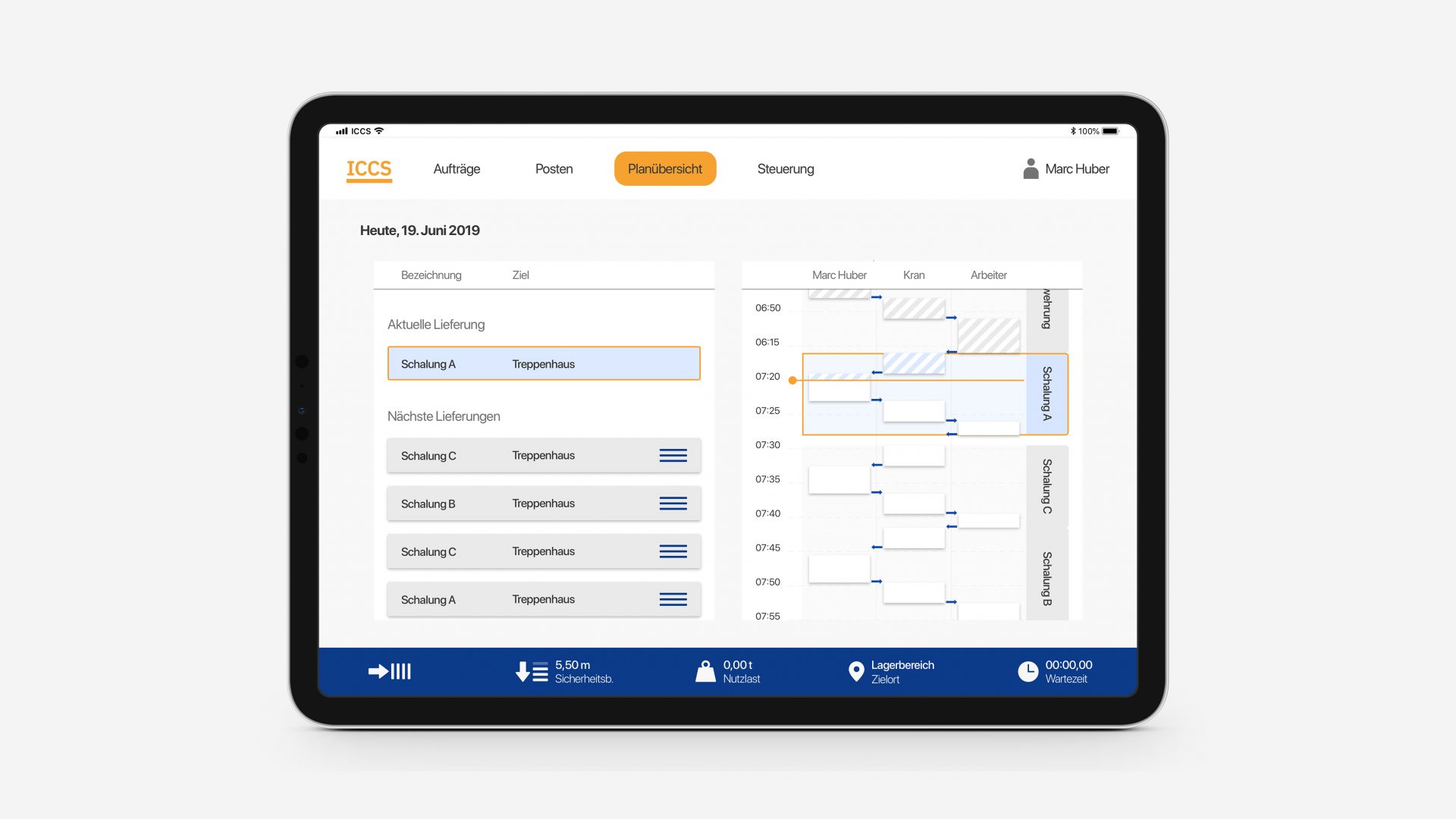

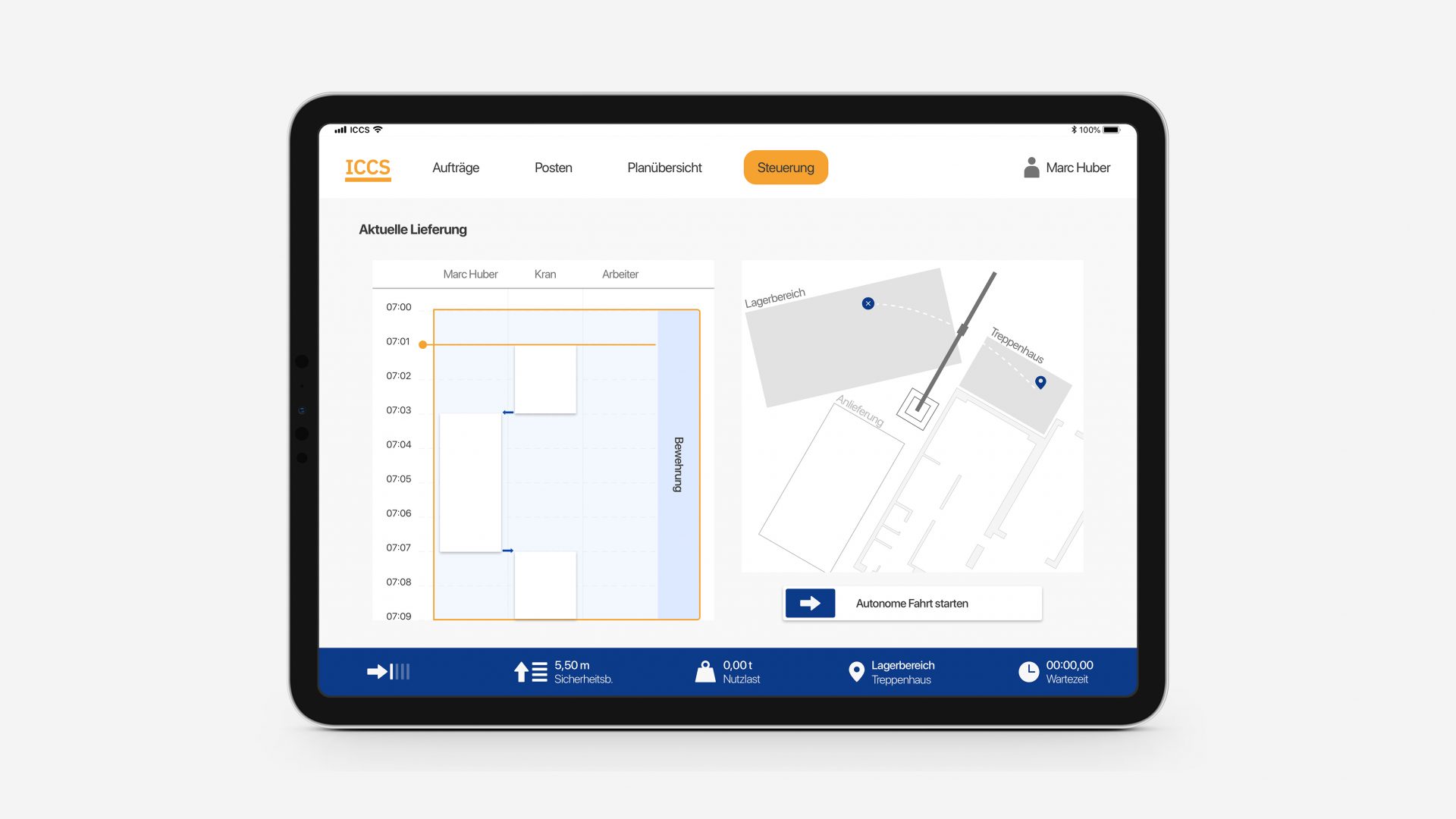

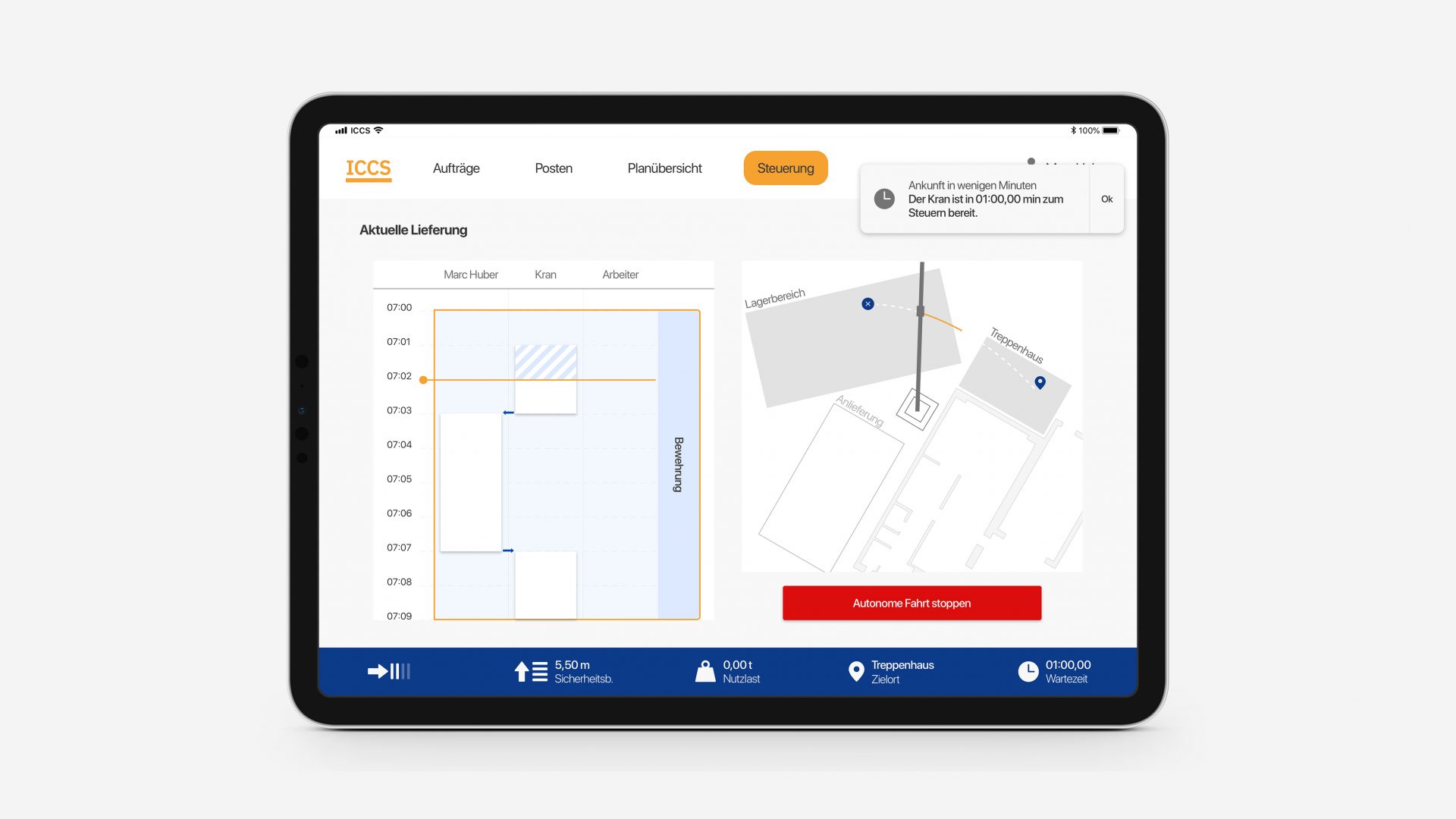

In the following gallery you can see a selection of the developed User Interface Screens.

Focus: Execution

The execution refers to the actual work of the crane operator. Here the individual deliveries of the items are processed, checked and, if necessary, adjusted. The main work of the crane operator is the movement of materials.